Jul 13th 2021

ThermoFlex Plus vs. ThermoFlex Turbo: What Is The Difference?

ThermoFlex is a go-to HTV line for decorators who want a soft feel, a clean matte finish, and results that last wash after wash. But if you’ve ever stared at ThermoFlex Plus and ThermoFlex Turbo wondering which one to grab… you’re not alone.

They look similar. They cut similarly. But they shine in different situations.

Let’s break it down in the simplest way possible.

What ThermoFlex Plus and Turbo Share

Before we talk differences, here’s what you get with either option:

- Soft, matte, professional finish

- Easy cutting and weeding on most vinyl cutters

- Durable, long-lasting hold when applied correctly

- Great for everyday apparel like tees, hoodies, and accessories

So you’re not choosing between “good and bad.” You’re choosing between “best for this job” and “best for that job.”

The Real Differences

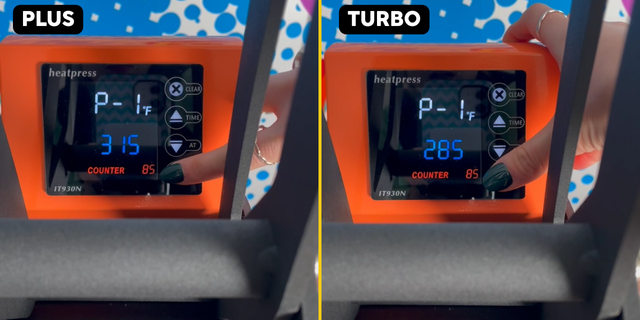

Press Time & Temperature

- ThermoFlex Plus:

Likes higher heat and a longer press—typically around 315–330°F for ~15 seconds. - ThermoFlex Turbo:

Built for lower temps and speed—usually 265–300°F for just 3–5 seconds.

Put simply: Plus = classic press. Turbo = fast press.

Fabric Compatibility: Where Each One Wins

Use ThermoFlex Plus for:

Plus is your reliable, standard-garment champion.

Use ThermoFlex Turbo for:

- Nylon and coated materials

- Athletic and performance gear

- Stretchy and heat-sensitive fabrics

- Jobs where speed matters

Turbo is your problem-solver for tricky fabrics and fast production.

The Simple Rule

If you remember nothing else, remember this:

✅ Standard garments? Grab ThermoFlex Plus.

✅ Tricky fabrics or need speed? Grab ThermoFlex Turbo.

Final Thoughts

Think of ThermoFlex Plus like your everyday workhorse—dependable, easy to use, and perfect for most apparel you press.

ThermoFlex Turbo is the flexible specialist—low-temp, fast-press, and ready for nylon, stretch, or anything heat-sensitive.

If you decorate a wide mix of garments, having both on hand means you’ll always be covered.